Powerlink Remote Heat Radiation Generator Comes

The cooling system of diesel generator sets plays an important role in the stable operation of the equipment. Scientific heat balance design can significantly improve the efficiency of the unit operation and reduce energy consumption.

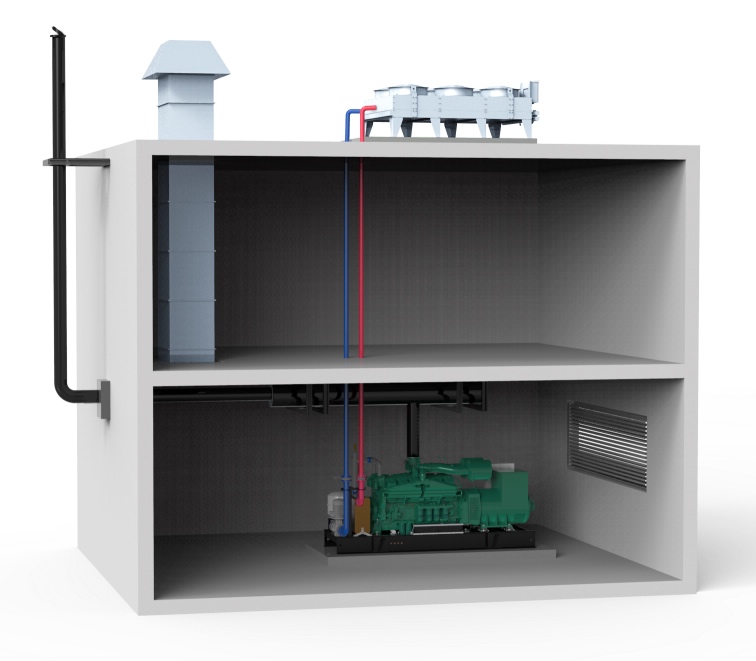

In urban buildings, the most effective space must be taken into account in the reasonable arrangement of equipment. How to meet the requirement of heat dissipation when the generator set is limited by the ventilation condition of the installation site, especially when installed in the basement, the space is closed?

There is a special demand for noise suppression in commercial center and residential area, while the traditional heat dissipation method of generator set will produce great noise. How to optimize the cooling system and reduce the noise greatly?

Powerlink remote heat radiation diesel generator set, based on the need for thermal balance and noise, and optimal investment cost control, provides you with a set of scientific and feasible solution of cooling system is to adopt the combination of independent heat exchanger and remote radiator, so that the heat dissipation of the engine is no longer restricted by space, and the heat balance and noise of the unit can be well controlled.

Mainly used in commercial buildings, hotels, hospitals, entertainment, fitness clubs, schools, residential areas, stations, airports and other areas where the installation space is limited and low noise requirements, and the environment temperature is higher.

Both the generator set and the remote radiator are highly integrated modular structure, which can be installed and put into use quickly;

Low noise. The sound pressure level of the 1000KVA generator set is less than 72dB (A) @ 7m when it is full load;

It is not limited by the space area, it runs stably and the heat dissipation effect is good;

Remote radiator can choose horizontal water tank or cooling tower;

Flexible and convenient operation, remote monitoring and unattended!

Low operating and maintenance cost, overhaul period up to 20000 hours;

Low investment cost, short recovery period.